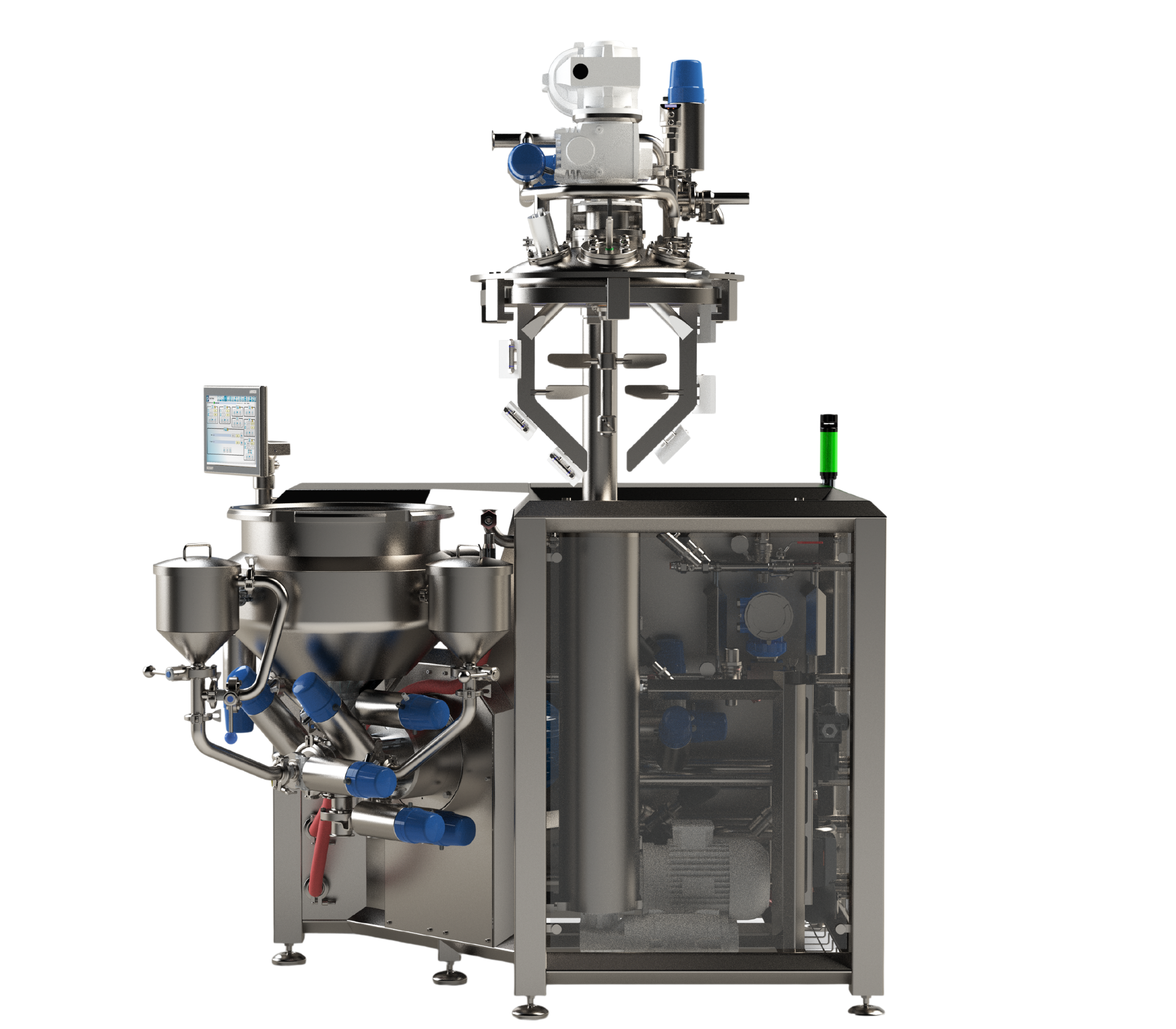

Our Vacuum Reactor is an advanced solution specially tailored to meet the formulation and homogenization needs of the pharmaceutical, cosmetic, health and personal care industries. It has been specially designed to accommodate a wide range of viscosities, thanks to the inclusion of a rotor-stator homogenizer.

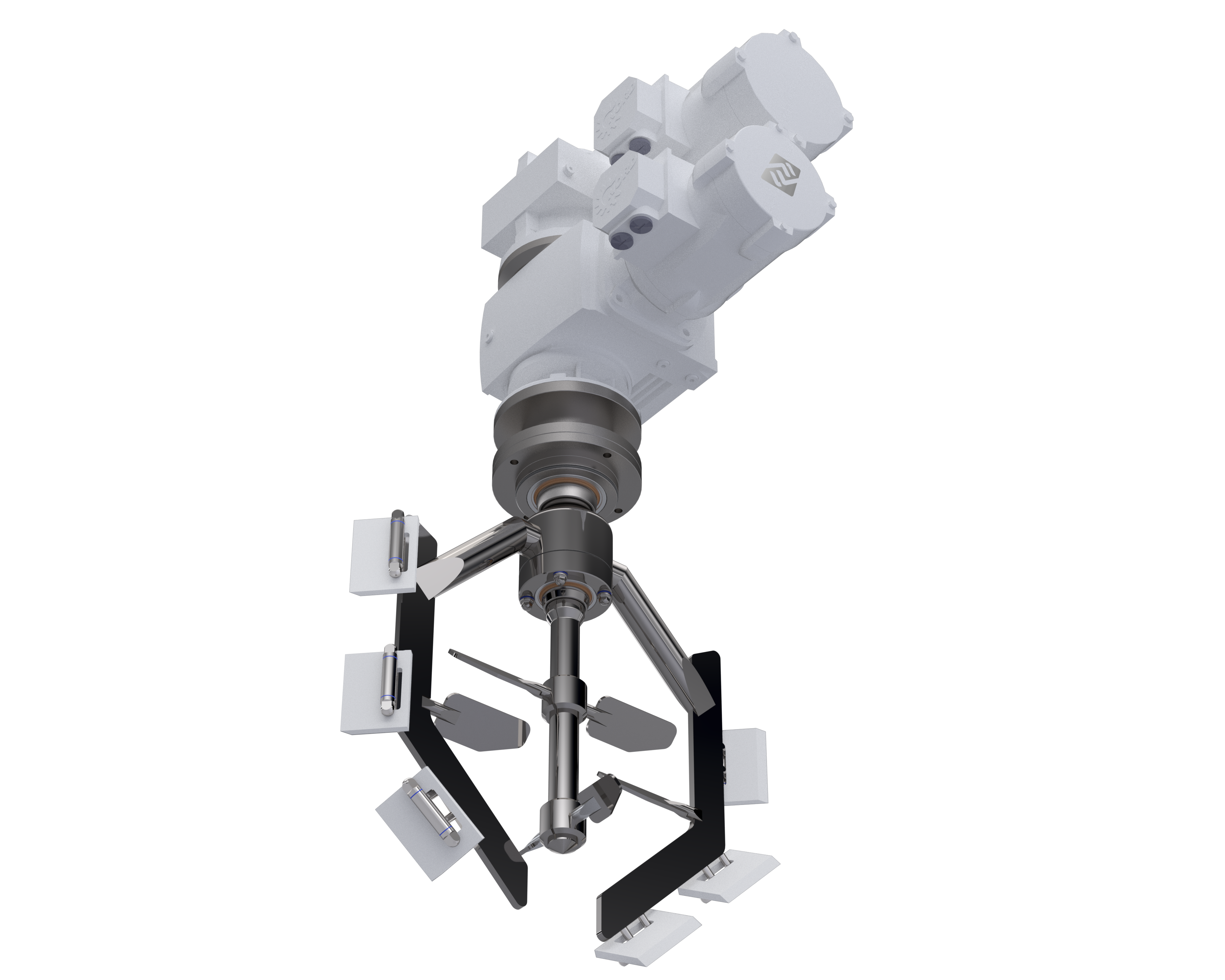

This homogenizer integrated into our Vacuum Reactor plays a crucial role in achieving exceptional homogenization results. This specialized component consists of a rotor and a stator, that work together to create a powerful shearing action. As the rotor spins, it generates high shear forces that effectively break down particles, disperse ingredients, and facilitate the uniform mixing of substances across a wide range of viscosities.

The versatility of our Vacuum Reactor enables it to handle various pharmaceutical and cosmetic semi-solid formulations, including creams, ointments, gels, lotions, and pastes. It can efficiently process both water-based and oil-based formulations, accommodating a diverse range of active ingredients and excipients. This flexibility makes our Vacuum Reactor an indispensable tool for pharmaceutical and cosmetic processes.

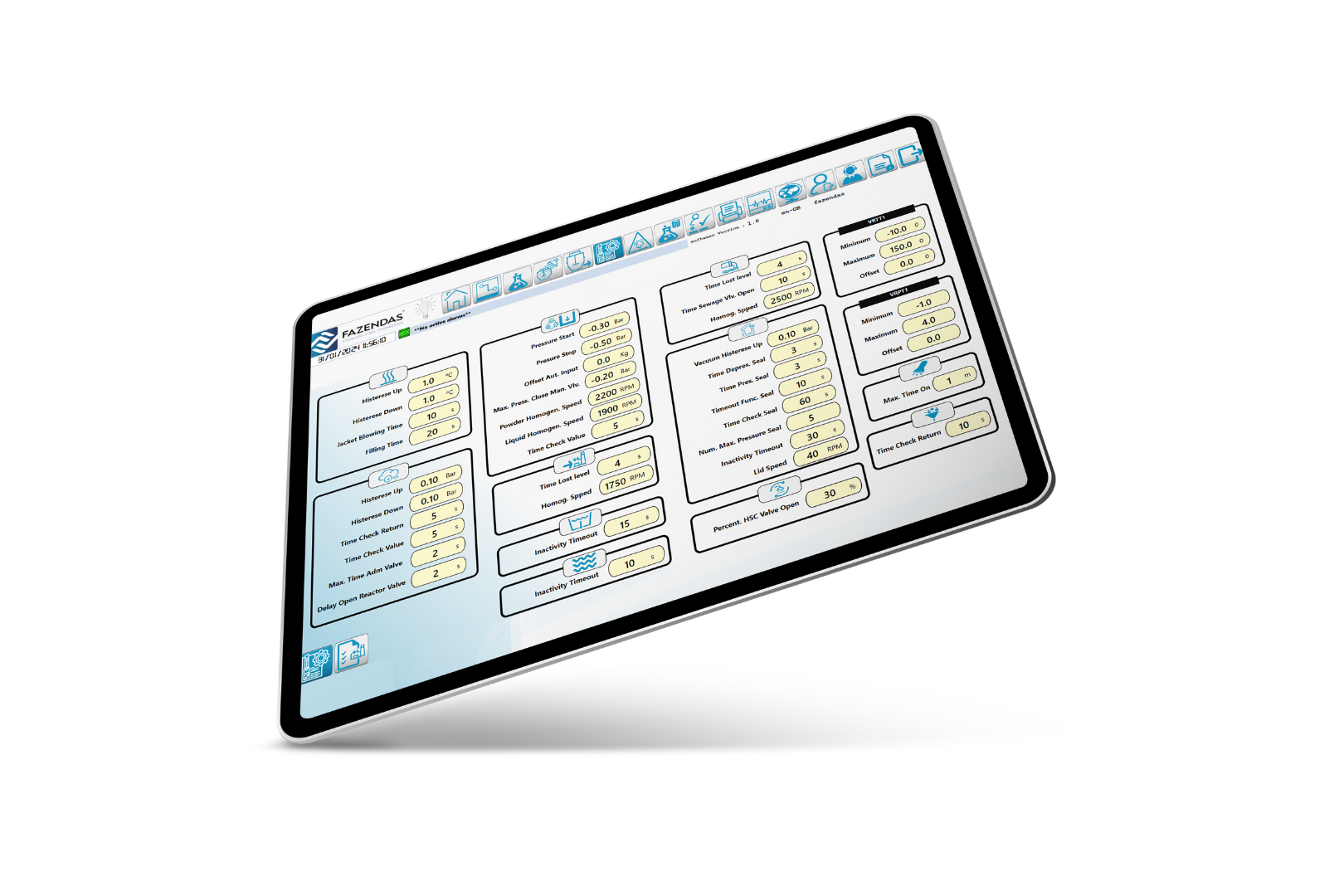

Equipped with intuitive controls, our Vacuum Reactors allow operators to monitor and adjust parameters such as temperature, vacuum level, rotational speed, and processing time for an excellent homogenization that creates high-quality, safe and reliable semi-solid products.